PRO Refrigeration Expands PROGreen Series With CO₂-Based PG50 Milk Chiller for Mid-Size Dairies

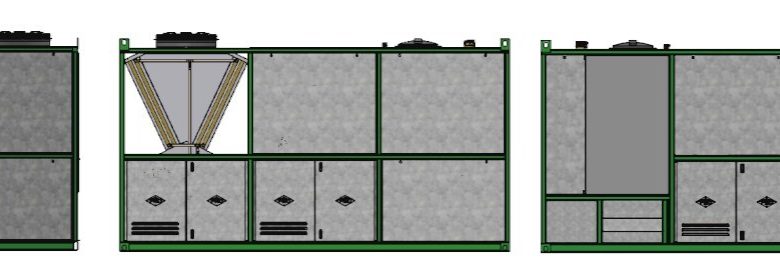

PRO Refrigeration has expanded its PROGreen Series with the launch of the PROGreen 50 (PG50), a new CO₂-based milk cooling system designed for mid-size dairy operations. The system covers cooling loads from 20 to 40 refrigeration tons and is aimed at making natural-refrigerant cooling accessible to a broader segment of the dairy market.

According to the company, the PG50 is sized and priced to meet the needs of approximately 80% of dairy farms in North America, addressing growing industry demand to move away from synthetic refrigerants toward long-term, environmentally sustainable alternatives.

The PG50 builds on PRO Refrigeration’s experience with CO₂-based systems, which began nearly five years ago with the installation of its first PROGreen 100 HP system. PROGreen units are currently being field-tested across multiple large dairies in California, serving more than 50,000 cows.

Designed specifically for mid-size dairies, the PG50 targets farms that require a natural-refrigerant solution but do not have the scale or budget to justify larger CO₂ platforms. The company states that the system offers a practical option for both retrofit projects and new dairy facilities.

Cost Reduction Through Proven Design

To improve affordability, PRO incorporated design elements from its established PRO4 Series. By using an existing chassis and manufacturing footprint, the company aims to reduce tooling costs and streamline production while maintaining performance.

This approach allows PRO to leverage existing supply chain partners, manufacturing workflows, and tooling, while minimizing cost premiums typically associated with CO₂-based refrigeration systems.

Incentives and Waste Heat Recovery

While CO₂ systems continue to have higher upfront costs compared with synthetic refrigerant systems, PRO says the PG50 narrows this gap through integrated waste heat recovery. The system converts recovered heat into up to 180°F hot water, which can significantly reduce fossil fuel consumption on dairy farms.

In California, PG50 installations may also qualify for financial incentives through the California Air Resources Board’s (CARB) Funding Agricultural Replacement Measures for Emission Reductions (FARMER) and FRIP programs. Eligible farms can receive up to $60,000 per system when replacing synthetic refrigerant equipment of equal or greater capacity.

Advanced Controls and Monitoring

The PG50 includes a range of next-generation features, including an upgraded controls platform with expanded I/O capabilities, real-time energy monitoring, and remote system access. The CO₂ circuit has been redesigned for improved efficiency across the 20–40 RT operating range, with optimized evaporator and desuperheater configurations.

Additional enhancements include improved coolant tank instrumentation, integrated waste heat recovery with monitored flow modulation, and onboard system diagnostics.

“Our goal has always been to make CO₂ a practical, high-performance option for the industries we serve,” said Jim Vandergiessen, CEO of PRO Refrigeration. “The PG50 brings natural refrigerant cooling into a size and price range that fits most U.S. dairies and opens several other markets to CO₂.”