KoCoS Unveils New INDEC VD 400 Dud Detection System for Food & Beverage Packaging

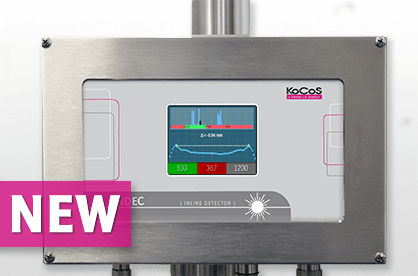

KoCoS Messtechnik AG has introduced its latest innovation, the INDEC VD 400 dud detection system, designed to identify defective, under-vacuumed, or poorly sealed bottles, jars, and cans in high-speed production environments.

The new system enhances quality assurance processes in food and beverage manufacturing by using advanced optical laser technology to analyze container caps with high precision. It detects dud containers regardless of cap color, surface texture, or material, allowing manufacturers to maintain product safety and reduce waste.

Advanced Technology & Easy Integration

The INDEC VD 400 features improved sensor mounting options, flexible design, and FDA-compliant construction, enabling seamless integration into various packaging lines. The system is engineered to work at high throughput rates while maintaining reliable and repeatable measurement accuracy.

Enhanced Software Capabilities

KoCoS has equipped the system with new PC-based software that offers real-time monitoring, centralized evaluation, and advanced statistical analysis. Operators can easily visualize performance data and optimize production processes.

Company Statement

Holger Ackermann, Product Manager at KoCoS, said the new system addresses modern packaging challenges while prioritizing ease of installation and user-friendly operation.

With the INDEC VD 400, KoCoS continues expanding its portfolio of precision measurement and inspection solutions for global industrial sectors.